Optimize Your Torque Management with Torque View

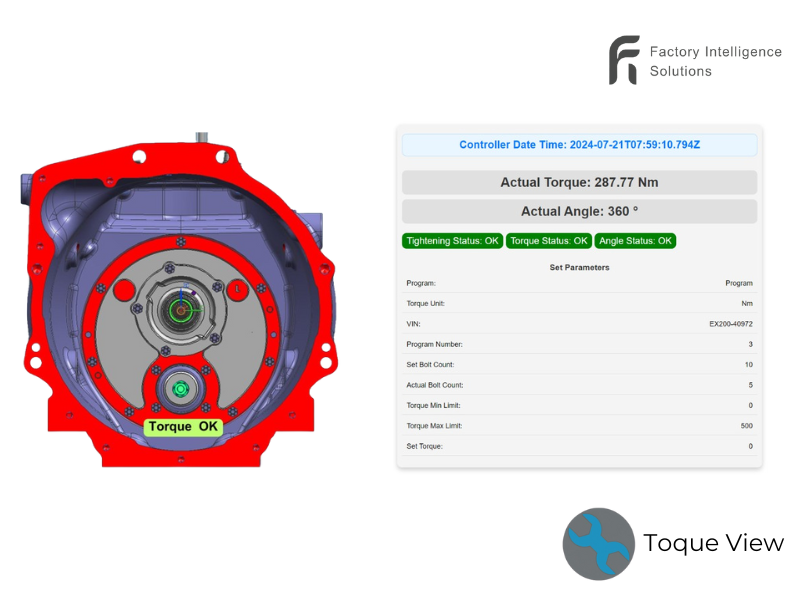

Torque View is a streamlined solution designed to manage and visualize torque and angle data efficiently.

Key Features of Torque View:

-

Real-Time Data Monitoring: Track torque and angle data in real-time to ensure that each tightening operation is performed within specified limits.

-

Comprehensive Data Storage: Capture and store detailed tightening data with the following fields:

Explanation of Data Captured by Torque View System:

-

timestamp: Records the exact date and time when the data was captured. -

torque: Represents the measured torque applied during the tightening process. -

angle: Indicates the angle at which the torque was applied. -

numberVIN: Stores the Vehicle Identification Number or similar identifier for the part being tightened. -

parameterSetID: Identifies the specific set of parameters used for the tightening process. -

batchSize: Represents the total number of components in the batch. -

batchCounter: Tracks the current position within the batch. -

tighteningStatus: Provides the status of the tightening operation (e.g., completed, in-progress). -

batchStatus: Indicates the overall status of the batch (e.g., passed, failed). -

torqueStatus: Shows whether the applied torque is within acceptable limits. -

angleStatus: Displays whether the applied angle meets the required specifications. -

torqueMinLimit: Defines the minimum acceptable torque limit. -

torqueMaxLimit: Defines the maximum acceptable torque limit. -

torqueFinalTarget: Specifies the target torque value to be achieved. -

Customizable Data Visualization: Utilize our customer-based system to visualize and interpret torque and angle data, ensuring that all tightening operations meet your quality standards.

-

Enhanced Reporting: Generate detailed reports and analyze trends to make data-driven decisions and optimize your tightening processes.

Transform your torque management practices with Torque View. Enhance data accuracy, streamline operations, and improve quality control today.